Stellenbosch University Launches Student Innovations With Ansys

“My Ansys simulation helped me explore different materials and thicknesses to optimize the assembly for mass and volume, as well as structural and thermal properties.” — Albert Lombard, graduate student, Stellenbosch University

For decades, Stellenbosch University has propelled satellite innovation in South Africa and across the globe. Ansys software and Ansys Innovation Courses help students continue this legacy.

You might not think much about satellites, but more than 10,000 circle Earth every day. Barely visible in the night sky, these orbiting satellites silently monitor weather and atmospheric conditions; conduct geographic studies; take photos; and transmit radio, television, internet, and geolocation signals.

Many of these satellites and their underlying technology systems have their roots at Stellenbosch University in Western Cape, South Africa. A team from the university launched the country’s first satellite in 1999, called SunSat. Carrying NASA experiments and a high-resolution imager, SunSat orbited Earth every 100 minutes, traveling at an incredible speed of 16,800 miles per hour.

Satellite innovation at Stellenbosch University has continued at a fast pace ever since. The university has launched startup businesses that lead the global aerospace industry and driven groundbreaking advancements in satellite design, power, and functionality.

Supported by the Ansys Academic Program and Qfinsoft, an Ansys Authorized Channel Partner, students, researchers, and educators at Stellenbosch University gain access to advanced simulation tools used by industry leaders worldwide.

Software from Ansys, part of Synopsys, has proven critical. Purpose-built for complex challenges like finite element analysis, thermal studies, digital mission engineering, and systems analysis, Ansys solutions provide aerospace researchers with a unique physics-based modeling environment. They can verify both platforms and payloads under realistic mission conditions and across dynamic timeframes.

The university has created a hands-on learning platform for its engineering students that exposes them to real-world design challenges as well as best practices like simulation. Each year, undergraduate students base their final-year research projects on updates and refinements to PocketQube, a class of miniature satellites developed at Stellenbosch University starting in 2023.

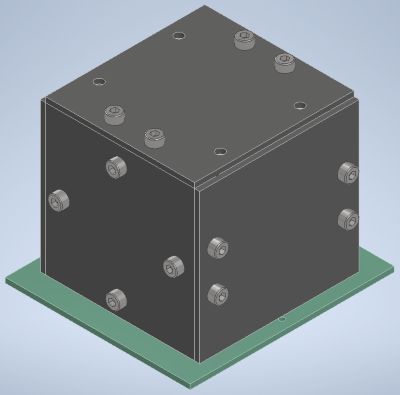

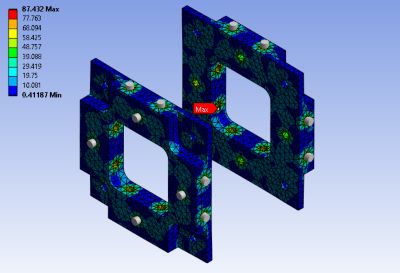

Albert Lombard’s solar panel design included two brackets fastened to the cube’s backplate, four threaded rods that mount the panels to the brackets, and 16 spacers. The design is shown both with the body-mounted solar panels included (left) and without (right).

PocketQube: Small Size, Big Research Opportunities

Measuring just two inches square, tiny PocketQube satellites are an important new class of spacecraft that has yet to be commercialized and widely used. But they have enormous potential, according to Willem Jordaan, associate professor of electrical and electronic engineering at Stellenbosch University.

“Miniaturized satellites are easy to launch, fast to engineer, and have a low barrier to market entry,” explains Jordaan. “They may eventually be used at scale in the global satellite industry to serve regions like Africa where communications systems are lacking. PocketQubes also represent an ideal platform for educational institutions as a learning tool and technology demonstration.”

Up to now, a total of 15 engineering students at Stellenbosch University have worked on innovations to the foundational components and designs for a PocketQube as part of their undergraduate thesis requirement.

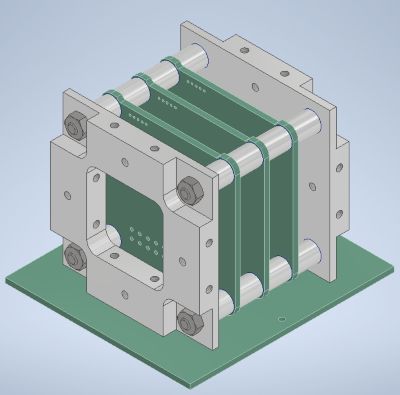

A meshed model of the new PocketQube design, complete with solar panels, showed good structural results with no stress singularities. The design is shown both with panels and the deployment mechanism included (left) and without (right).

Ansys Innovation Courses Help New Users Take Flight

Albert Lombard, a mechatronic engineering student who graduated in December 2024 and is now pursuing his master’s degree at Stellenbosch University, was one of those students.

His senior-year research project, titled “Development of a PocketQube Structure and Solar Panel Deployment Mechanism,” relied on using Ansys software to study the thermal and mechanical impacts of installing solar panels and the mechanical brackets that hold them in place.

As Lombard began his research, there was only one obstacle: He had never used Ansys Mechanical structural finite element analysis software, which was the natural solution. “My project supervisor proposed Ansys to me. He’s had some previous positive interactions with Ansys, and he’s used Ansys software himself,” Lombard says. “He pointed me to some specific capabilities that were relevant to my research.”

Lombard quickly discovered the online library of free Ansys Innovation Courses, including one that perfectly matched his research topic, called “Modal Analysis of a Satellite.” Within a few months, he showed his first simulation results to Jordaan, his thesis adviser.

“At Stellenbosch University, we try to instill a sense of independence in young engineers, and Lombard’s self-learning of Ansys software is a perfect example of that mindset,” says Jordaan. “If you’re working as an aerospace engineer, a lot of your research is going to be unstructured. There are great resources like Ansys Innovation Courses out there. We can guide students to some extent, but then they need to find and apply those resources independently.”

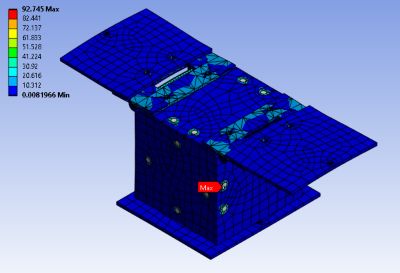

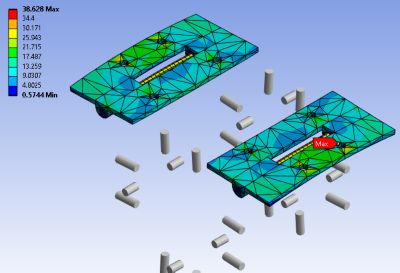

Ansys Mechanical structural finite element analysis software enabled Lombard to analyze thermal effects that occur while the miniature satellite is orbiting. The thermal hot spots are caused by radiation and are shown here on the body-mounted solar panel (left), brackets (middle), and hinges (right).

Boosting Student Research to a Professional Level

Supported by Ansys software and Qfinsoft, Lombard’s research findings highlighted some key challenges — and solutions — for supplementing tiny PocketQube satellites with even smaller solar panels and brackets.

“There are some complex multiphysics effects involved in adding deployable solar panels,” says Lombard, “especially since there is little to no extra volume or mass for unnecessary assemblies and material. The panels need to act as structural components, as well as generate enough power to support communication and other functions. But they also need to be as small and lightweight as possible.

“The crucial moment of launch was a special focus of my research,” he continues. “The PocketQube has to survive the thermal and mechanical forces of launch with its solar panels intact. My Ansys simulation helped me explore different materials and thicknesses to optimize the assembly for mass and volume, as well as structural and thermal properties.”

Lombard’s physical prototype is being tested in a high-altitude balloon launch at Stellenbosch University.

Lombard also had to consider extensibility, component reuse, and ease of manufacturing, assembly, and integration when designing the new solar panels.

In the end, Lombard’s simulations — which include detailed meshing — are helping to further advance Stellenbosch University’s PocketQube designs.

“Lombard’s research verified some solar panel designs, which are practically feasible,” says Jordaan. “We’re physically testing his concept by launching it to 50,000 feet in a high-altitude balloon. Based on our experience with Ansys software at Stellenbosch University, we fully expect that physical test to verify the simulation results.”

As for Lombard, he’s grateful for the chance to perform this kind of advanced research and simulation while still an undergraduate. “Structural and thermal analysis are used over many different applications,” he says. “As a professional engineer, I expect to encounter other problems where I will use the skills I obtained in this project.”

To discover additional learning opportunities and a wide range of resources, visit the Ansys Academic Program. Level up your learning by exploring Ansys Innovation Courses.

Unlock the world of satellite constellations with this comprehensive e-book from Ansys, part of Synopsys. Learn about satellites’ advantages and challenges, as well as how cutting-edge technologies like AI, edge processing, and advanced design software are reshaping the aerospace industry.

Presented By:

Susan Coleman

Senior Director, Academic and Startup Programs.

Related Resources

When designing components for the space environment, significant attention must be put into designing for intense vibration, shock, and thermal environments. During the development of a new reaction wheel, NewSpace Systems (NSS) conducted extensive environmental testing to examine the performance and predict the lifetime of the wheel. Special attention was to be given to the electronics and bearings, as these components had the most significant impact on the lifetime of the wheel

The Aquila D01 sun sensor from NewSpace Systems (NSS) is a proven and reliable system with extensive in-orbit heritage. It features a detector housed beneath a metal mask with precision-cut slits. As sunlight passes through these slits, it creates a unique one-dimensional brightness profile on the detector. This pattern is then analysed to determine the sun's position. In 2022, the linear array used in the Aquila D01 was discontinued, prompting an effort to redesign the sun sensor to meet updated component availability.

The Aerospace Systems Research Institute (ASRI) aims to strengthen South Africa’s advanced manufacturing capabilities while inspiring the next generation of aerospace engineers. To support these goals, the ASRI team is actively engaged in multiple award-winning projects.

Targeting sustainability goals can present challenges in some industries, as notable carbon-reduction initiatives like Race to Zero aim to halve emissions by 2030 and reach net zero by 2050. This has increased interest in direct air capture (DAC) technology, which removes carbon dioxide (CO2) directly from the atmosphere and enables it to be stored underground or converted into climate-neutral carbon products.