How Mesh Quality, Refinement Strategies, and Convergence Studies Improve Simulation Accuracy in Ansys Mechanical

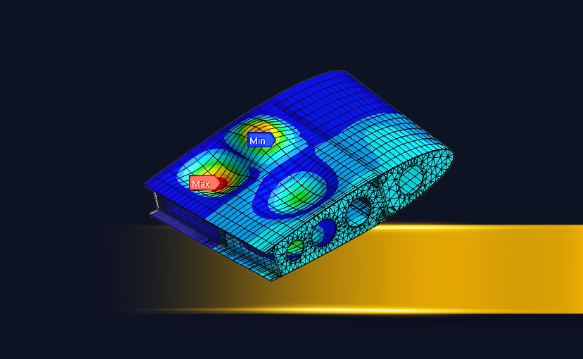

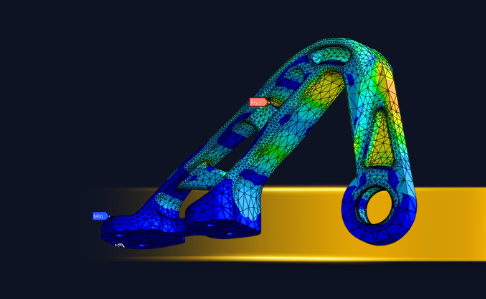

Getting accurate simulation results isn't just about running the analysis—it starts with a high-quality mesh! But how fine should your mesh be, and how do you balance accuracy with computational efficiency? Watch this video as we explore mesh refinement strategies in Ansys Mechanical, covering the impact of mesh quality on simulation accuracy, the differences between global and local mesh controls and when to refine, conducting mesh dependence studies to ensure reliable and converged results and a hands-on demo of mesh parametric studies and automatic mesh refinement in Ansys.

Presented By:

Jeanri van Rensburg

Senior Engineer.

Jeanri van Rensburg is a Senior Application Engineer specialising in Ansys Mechanical, Fluent, LS-DYNA, optiSLang, and Granta. She applies advanced FEA and CFD expertise to solve complex engineering challenges and drive innovation through simulation.

Related Resources

Simulating massive structures like aircraft wings, nuclear power plants, and large assemblies can quickly turn into a computational nightmare. But what if you could break these down into smaller, more efficient parts while maintaining accuracy?

Watch this video as we explore mesh refinement strategies in Ansys Mechanical, covering the impact of mesh quality on simulation accuracy, the differences between global and local mesh controls and when to refine, conducting mesh dependence studies to ensure reliable and converged results and a hands-on demo of mesh parametric studies and automatic mesh refinement in Ansys.

This technical session covers how to perform ROPS (Roll-Over Protective Structures) and FOPS (Falling-Object Protective Structures) analysis using Ansys Mechanical and LS-DYNA in the Ansys Workbench environment, tailored for the mining industry.

Discover how Rocky DEM combined with OptiSLang can be used to optimise the design of vertical mine ore passes. In this technical session, we explore how adjusting the angles of the second and third sections affects ore flow, wear, and overall system efficiency. With advanced simulation and automated optimisation, you’ll see how to find the best geometrical configuration to reduce blockages, cut down on maintenance, and boost productivity in mining operations.