Ansys and ATI FlyZero use Digital Engineering to Design Concept Aircraft

All major automotive original equipment manufacturers (OEMS) have announced that they are going fully electric within a few years, so the spotlight is turning toward the aviation industry to drastically reduce carbon emissions. While the aviation sector is much more difficult to decarbonize, many aviation leaders are vowing to reach net-zero carbon emissions goals by 20501, so OEMs in aviation are striving to adopt new initiatives and technologies to reach these goals safely.

By embracing digital transformation and integrating simulation into workflows, engineers can design cleaner, faster, and smarter systems that reduce carbon emissions, material use, and noise pollution. Digital engineering enables engineers to integrate sustainability best practices into all phases of the life cycle, including the concept design phase.

Concepting to Meet Goals

To support the commercial aviation industry’s goal to meet emission reduction targets2, Aerospace Technology Institute (ATI) FlyZero worked with Ansys solutions to develop three aircraft concepts with zero in-flight carbon emissions for use in 2030.

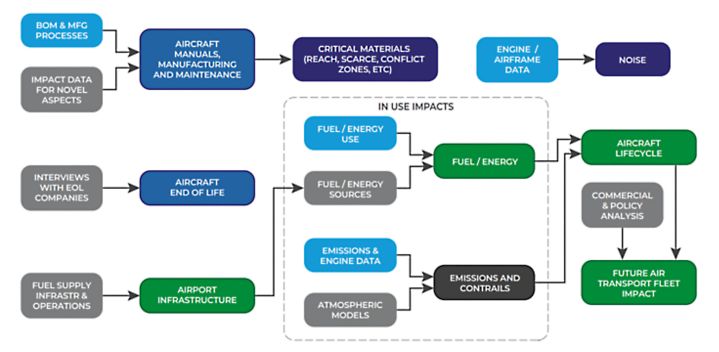

ATI FlyZero wanted to compare the sustainability impact of three benchmark aircraft against the three concept aircraft (Figure 1). The benchmark aircraft are hydrocarbon fuel kerosene aircraft that could be expected to be in service in 2030. The concept aircraft explore new propulsion technology, such as hydrogen combustion and hydrogen fuel cells with electric powertrain.

- FlyZero midsize using hydrogen combustion versus the benchmark midsize, which is an Airbus A330-200-like aircraft with expected 2030 improvements.

- FlyZero narrow using hydrogen combustion for propulsion, while the on-board power system is changed to fuel-cell technology versus the benchmark narrow, which is an Airbus A320-300-like aircraft with expected 2030 improvements.

- FlyZero regional using hydrogen fuel cells for propulsion and the power systems versus the benchmark regional, which is an ATR42-like aircraft with expected 2030 improvements.

The aircraft were divided into five main design modules:

- Airframe

- Propulsion

- Electrical systems

- Power systems

- Cabin

FlyZero used the materials data library in Ansys Granta MI and Ansys Granta Selector to establish reference data for the materials and manufacturing processes. This compares technical, cost, and sustainability information, supported by a streamlined life cycle analysis (LCA) tool and methodology (Eco Audit in Granta) and tools for screening restricted substances and social impacts. The Ansys software suite addresses materials information management for technical and sustainability information, with integration to engineering design processes:

- Coordination of the bill of materials (BoM) using Granta MI

- Assignment of reference data from MaterialUniverse

- Screening for restricted substances

- Calculation of the environmental impact for each line in the BoM

- Screening for social impacts

- Screening for environmental hot spots across the product life cycle

- Substituting material and manufacturing choices to improve the sustainability of the product (e.g., risk, environmental, social impacts) against technical design decisions

- Reporting to stakeholders

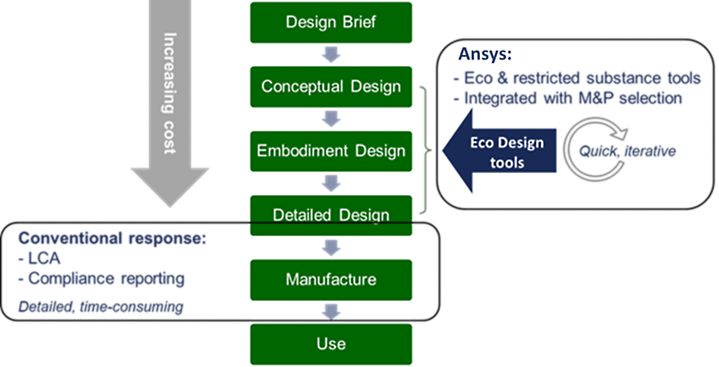

Figure 2 indicates where in the product development workflow the Ansys toolset can intervene early for sustainability assessment and trade-off decisions.

Determining the Impact

The FlyZero team determined the highest material environmental impact was carbon fiber-reinforced plastic (CFRP) used for the airframes of all aircraft. CFRP can replace steel and aluminium thanks to its high strength-to-weight ratio, which greatly improves fuel savings — CFRP density can be half of aluminium and four times lower than steel.

However, the materials and manufacturing process of CFRP and its low recyclability, should be re-evaluated against lower CO2 propulsion options. Bio-based carbon and recycling technology may present an opportunity for lower environmental impact, but it faces other challenges, such as low fire resistance and strength, and is currently still on the pathway to scalability.

Screening for restricted substances also indicated that plastics (including epoxy) contained some of the highest risks, followed by nickel-based materials. In terms of social performance, the list of elements with highest impact deviated from the lists of substances and materials highlighted as risks for the environmental and restricted substances lists, and instead identified elements having either price volatility due to geopolitical sourcing issues and/or scarcity.

Figure 3 identifies high-level stages of the design process and indicates the integration of Ansys materials software tools and data to enable quick screening of materials and manufacturing for effective eco design, with insight on end-of-life options. The concept design phase is a critical moment in the life of a product as this is the point at which materials, manufacturing, use phase design, and end-of-life decisions are essentially decided and 80% of life cycle impacts and costs are locked in. However, it is also the design phase with the most options (materials, processes, geometry, etc.), yet has the least amount of detailed information available due to supplier confidentiality and/or lack of primary measurements.

This work informed the FlyZero team of the environmental impact of the aircraft quantitatively (global warming potential, embodied energy) and qualitatively by identifying hazardous/restricted materials, security of supply or unethical sourcing, recyclability, etc. You can download the “ATI FlyZero – Sustainability Report” here. The results of this work will inform decisions for future research and development challenges, such as the need for material or manufacturing process substitution.

Learn more about how Ansys Granta MI can help your propulsion aircraft design by visiting our Ansys materials page.

Related Posts